Amid rising trade tensions between the US and China and geopolitical uncertainties elsewhere globally, many leading semiconductor manufacturers are considering shifting their production locations to more stable countries, and Vietnam is emerging as one of the top choices for undertaking semiconductor manufacturing projects.

Indeed, Vietnam is becoming an attractive destination for major companies in the semiconductor industry. With low labour costs, a strategic geographic location in Asia, and supportive investment incentives from the government, the country is drawing the attention of top technology corporations like Intel, Samsung, and NVIDIA.

Additionally, the increasing demand for technology and consumer electronics is driving investors to seek opportunities in this market. Following the COVID-19 pandemic, many companies are looking to diversify their supply chains to reduce risks, and Vietnam has become an appealing option in this context.

Vietnam is benefiting from the relocation of major electronics manufacturing plants from China, such as Foxconn, Samsung, and LG. This shift is driven by companies seeking more stable production environments amid global supply chain disruptions and increasing trade tensions, says Do Duc Hau, general director of Advantech Vietnam.

According to the executive, the supply chain has been reshaped into a 2.0 model, which includes the formation of eight new manufacturing regions. Southeast Asia is one of the key areas where companies are investing to establish new production hubs, with Vietnam being a preferred investment location for many major players in the semiconductor industry.

A recent Reuters report reveals several large companies are testing their production capabilities in Vietnam, especially as the government is investing in chip manufacturing infrastructure through military-run telecom group Viettel, with plans for operations to begin by 2030.

To achieve broader goals, the government is working to create an attractive business environment for chip manufacturers, offering various advantages. Concurrently, it is establishing comprehensive strategic partnerships with semiconductor powerhouses like the United States, Japan, and the Republic of Korea to facilitate investment from companies in these economies into Vietnam.

This is a unique opportunity for Vietnam to develop its semiconductor industry, leveraging these partnerships and favorable conditions to position itself as a competitive player in the global market, says Hau.

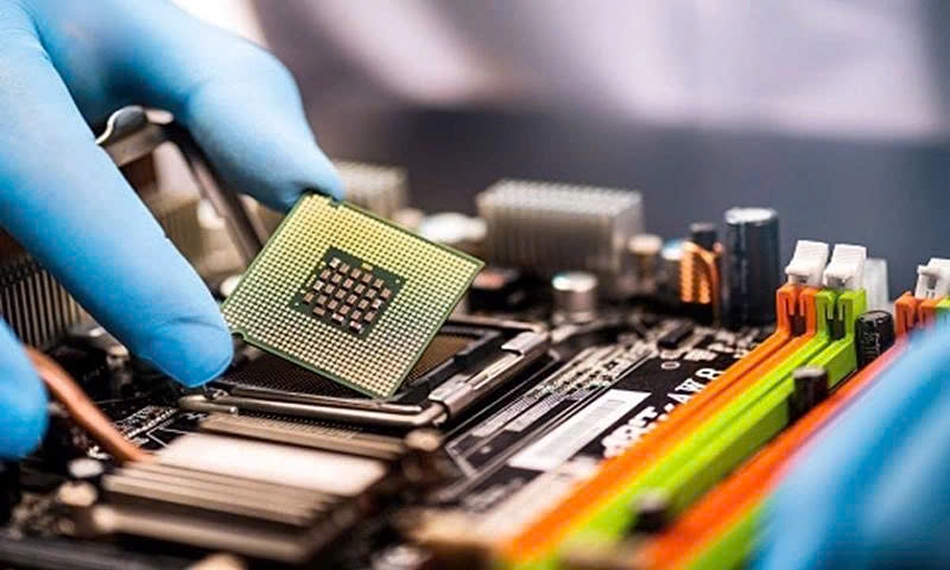

Furthermore, Vietnam has a rich and experienced labour force in the semiconductor sector, along with industrial infrastructure that meets the demands for chip production, assembly, and packaging.

The country’s semiconductor industry has actually been developing for more than 20 years, benefiting from a strong STEM (science, technology, engineering, and mathematics) resource base. Currently, there are about 40-50 companies operating in chip designing in Vietnam. The ecosystem includes more than 5,000 design engineers, who will be essential for future expansion in this field.

Despite having some semiconductor manufacturing facilities, the supply chain in the industry is yet to be fully developed in Vietnam. Many materials and components still need to be imported from abroad. The country faces challenges in developing advanced semiconductor manufacturing technology and investing in research and development that limit the industry’s ability to compete directly with more developed countries.

Although there are efforts to train engineers and experts in the semiconductor field, there remains a shortage of highly skilled and experienced personnel.

The government has recently approved the program “Developing Human Resources for the Semiconductor Industry by 2030, with a Vision for 2050.” By 2030, Vietnam aims to train and develop a high-quality workforce in the semiconductor industry, focusing on semiconductor chip design, packaging, and testing. The goal is to gradually master technology in semiconductor manufacturing, training at least 50,000 university-level professionals to support all stages of the semiconductor value chain.

By 2050, Vietnam aspires to have a strong workforce integrated into the global semiconductor value chain, capable of meeting the quality and quantity demands necessary for the growth of the semiconductor industry in Vietnam.

The solid foundation in human resources positions Vietnam well to enhance its capabilities in semiconductor design and production, enabling the country to attract more investment and expertise as the industry continues to grow.